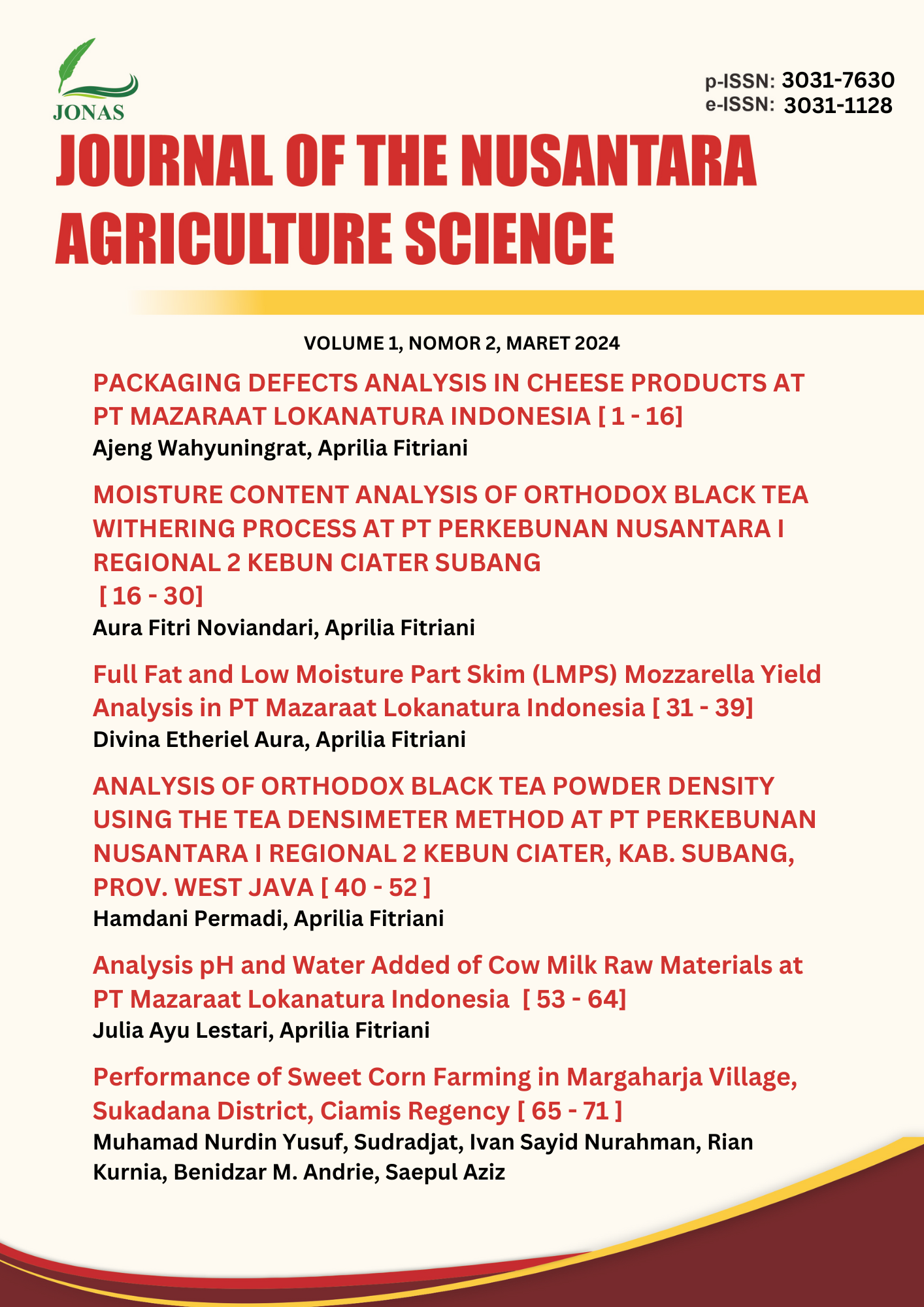

ANALYSIS OF ORTHODOX BLACK TEA POWDER DENSITY USING THE TEA DENSIMETER METHOD AT PT PERKEBUNAN NUSANTARA I REGIONAL 2 KEBUN CIATER, KAB. SUBANG, PROV. WEST JAVA

Keywords:

Black tea, orthodox system, tea density, tea qualityAbstract

PT Perkebunan Nusantara I Regional 2 Ciater Plantation is engaged in the processing, management and marketing of black tea plantation products. The processing method used is the orthodox method, resulting in tea with a distinctive aroma and color. One of the quality control efforts on dry sorted tea products is the density test. Density is one of the indicators of tea quality control that affects the distribution and packaging process of tea powder. This study aims to determine the results of density analysis of orthodox black tea for 10 days, then determine the results of quality control with the P control map and determine the factors that cause density quality discrepancies. The method used in the density analysis of orthodox black tea is the tea densimeter method by tapping the powder 35 times. The result of powder density read in the measuring cup represents the volume of tea powder. The types of tea analyzed include BOPF, PFANN, Dust, PFANN II, Dust II and FANN II. The results showed that there were several deviations in the types of powder BOPF, PFANN, FII and Dust II which can be seen on the P control map. Factors that cause discrepancies in density values are the receipt and handling of raw materials. So it is necessary to do a good handling of raw materials by testing data worth processing in order to produce powder that meets the standards.

References

Adnan, M., Ahmad, A., Ahmed, A., Khalid, N., Hayat, I., & Ahmed, I. (2013). Chemical Composition and Sensory Evaluation of tea (Camellia sinensis) Commercialized in Pakistan. Pakistan Journal of Botany, 45(3), 901–907.

Aloo, O. S., Kim, D.-G., Vijayalakshmi, S., Aloo, D. O., Ochola, C. O., & Oh, D.-H. (2024). Polyphenol constituents and impacts of fermented teas (Camellia sinensis) in human wellness. Food Bioscience, 60, 104389.

Amarta, Y. Y., & Hazimah. (2020). Pengendalian Kualitas Produk Dengan Menggunakaan Statistical Processing Control (Spc) Pada Pt Surya Teknologi. Prosiding Seminar Nasional Ilmu Sosial Dan Teknologi (SNISTEK), 218–228.

Annisa, N. (2021). Perbandingan Efektivitas Peta Kendali Decision On Belief dan Peta Kendali P pada Pengendaian kualitas Produk.

Barbosa-Canovas, G. V., Ortega-Rivas, E., Juliano, P., & Yan, H. (2005). Food Powders: Physical Properties, Processing, and Functionality. Food Engineering Series. (USA): Kluwer Academic/Plenum Publishers.

Dewi, S., & Purnomo. (2019). Mutu Petik Teh (Camellia sinensis (L.) O. Kuntze) di Kebun Bedakah, Wonosobo, Jawa Tengah. Buletin Agrohorti, 7(1), 337–342.

Ferdiansyah, M. R., Zamzami, A., & Purwono. (2023). Evaluasi Metode Pemetikan Teh (Camellia sinensis (L.) O. Kuntze) untuk Memproduksi Teh Hijau di Perkebunan Teh Negara Kanaan, Bandung. Buletin Agrohorti, 10(3), 440–449. https://doi.org/10.29244/agrob.v10i3.46486

Gaspersz, V. (2001). ISO 9001:2000 and Continual Quality Improvement. PT Gramedia Pustaka Utama.

Graham, H. N. (1992). Green tea composition, consumption, and polyphenol chemistry. Prev Med, 21, 33.

Immanniaty, A.-N., & Juwitaningtyas, T. (2022). Analysis Of Tea Shoots Worth Processing (APLO) In The Raw Materials Of Orthodox Black Tea With Mechanical Picking Method At PT. Perkebunan Nusantara VIII Kebun Kertamanah Bandung, Jawa Barat. Jurnal Rekayasa Dan Manajemen Agroindustri, 10(3), 342. https://doi.org/10.24843/jrma.2022.v10.i03.p11

Jolvis Pou, K. R. (2016). Fermentation: The Key Step in the Processing of Black Tea. Journal of Biosystems Engineering, 41(2), 85–92.

Kushwahaa, D. K., Thomasa, E. V., Maitib, B., Ghosha, B. C., & Dec, B. (2015). Assessment and Optimization of Bulk Density and Angle of Repose of Tea Leaves for Metering Device Using Desirability Function. International Journal of Scientific Engineering and Technology, 4(2), 36–39.

Lumay, G., Boschini, F., Traina, K., Bontempi, S., Remy, J. C., Cloots, R., & Vandewalle, N. (2012). Measuring the flowing properties of powders and grains. Powder Technology, 224, 19–27.

Martin, L. C. (2007). Tea: The Drink That Changed the World. Tuttle Publishing, North Clarendon, U.S.A.

Montogomery, D. C. (2008). Introduction to Statistikal QualityControl. (6th ed.). New Jersey: Wiley.

Nazaruddin, & Paimin. (1993). Pembudidayaan dan Pengolahan Teh. Penebar Swadaya. Jakarta.

Owuor, P. O., & Orchard, J. E. (1992). Effects of storage time in a two-stage withering process on the quality of seedling black tea. Food Chemistry, 45, 45–49.

Po, K. R. J. (2016). Fermentation: The Key Step in the Processing of Black Tea. Journal of Biosystems Engineering, 41(2), 85–92.

Pou, K. J., Paul, S. K., & Malakar, S. (2019). Industrial processing of CTC black tea. In Caffeinated and Cocoa Based Beverages, 8, 131–162.

Prawira, M. I., Haryanto, S., Maulana, H., Shabri, & Rohdiana, A. (2019). Karakteritik sifat alir bubuk teh hijau yang diproses dengan metode penepung berbeda. Jurnal Sains Teh Dan Kina, 21(2), 85–95. https://doi.org/10.22302/pptk.jur.jptk.v21i2.147

Purba, Y. M. S., Yusasrini, N. L. A., & Nocianitri, K. A. (2021). Pengaruh Suhu dan Lama Pengeringan Terhadap Karakteristik Teh Herbal Matcha Daun Tenggulun (Protium javanicum Burm.F.). Jurnal Ilmu Dan Teknologi Pangan (ITEPA), 10(3), 400. https://doi.org/10.24843/itepa.2021.v10.i03.p08

Rocha, A., Romero, F., Miranda, D., Amorim, M., & Lima, R. M. (2023). Quality management practices to direct and control the accomplishment of project objectives in R&D units. Procedia Computer Science, 219, 36–43. https://doi.org/10.1016/j.procs.2023.01.261

Salsabila, Cut, N., & Hasni, D. (2023). Pengendalian Mutu Keringan Teh Hitam Menggunakan Metode Seven Tools di PT. Mitra Kerinci, Solok Selatan, Sumatera Barat. Jurnal Ilmiah Mahasiswa Pertanian, 8(3), 331–344. www.jim.unsyiah.ac.id/JFP

Sanyal, S. (2011). Tea manufacturing manual. Tea Research Association, Tocklai Experimental Station, Jorhat.

Schillinger, U., L.Ban-Koffi, & Franz., C. M. A. P. (2010). Tea, Coffee and Cacao. In Fermented Foods and Beverages of the World, (J. P. Tamang and K. Kailasapathy, eds.). CRC Press, New York.

Sinaga, S. T. D., Putri, S. H., & Pujianto, T. (2023). Analisis Pengendalian Kualitas Pada Proses Produksi Teh Hitam Menggunakan Metode Statistical Quality Control. Teknotan, 17(2), 153. https://doi.org/10.24198/jt.vol17n2.10

Tarwaka. (2004). Ergonomi Untuk Keselamatan, Kesehatan Kerja dan Produktivitas. UNIBA PRESS. Cetakan Pertama. Surakarta.

Teshome, K. (2019). Effect of tea processing methods on biochemical composition and sensory quality of black tea ( Camellia sinensis ( L .) O . Kuntze ): A review. Journal of Horticulture and Forestry, 11(6), 84–95.

Wakamatsu, J., Yamamoto, M., Kikuta, M., Tanaka, W., & Tominaga, R. (2024). Effect of shading on trichome formation and CAPRICE-like gene expression in tea (Camellia sinensis var. sinensis) leaves. Scientia Horticulturae, 330.

Winarno, F. G. (1995). Kimia Pangan dan Gizi. Gramedia Pustaka Utama.

Zhu, M.-Z., Wen, B., Wu, H., Li, J., Lin, H., Li, Q., Li, Y., Huang, J., & Liu, Z. (2019). The Quality Control of Tea by Near-Infrared Reflectance (NIR) Spectroscopy and Chemometrics. Journal of Spectroscopy, 2019(58), 1–11.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Hamdani Permadi, Aprilia Fitriani

This work is licensed under a Creative Commons Attribution 4.0 International License.